A Recycled-First Precinct – Keon Parade LXRP (Level Crossing Removal Project) – Economic Outcomes

The Recycled First Competition is an innovative initiative developed by the North Western Program Alliance (NWPA) aimed at promoting sustainability in infrastructure by driving significant economic value for the circular economy.

By addressing and solving key barriers to the use of recycled products, NWPA’s competition brought new, cost competitive recycled products to market, reducing both carbon emissions and waste, while supporting the creation of new jobs and local businesses.

The competition has fostered collaborative partnerships across the supply chain, opening up new procurement opportunities and driving industry wide cultural change. It has provided significant investment to facilitate the pathway to market for multiple recycled products and materials, while also removing perceived ‘green premiums’. The competition has created a ‘beacon’ for other industries, by generating a replicable model that demonstrates how to harness economic impact and shows the potential for long-term value creation using recycled products in infrastructure.

Describe WHAT you have done and HOW you have done it. Please provide a summary of your initiative, innovation, or approach.

The North Western Program Alliance (NWPA) is one of five Alliances delivering the Victorian Government’s landmark Level Crossing Removal Project (LXRP).

NWPA’s Recycled First Competition is a transformative sustainability initiative aimed at overcoming barriers to the use of recycled materials in infrastructure projects. It has been running since 2021 when LXRP challenged NWPA to develop an ongoing industry changing “beacon-project” to support and accelerate best practice sustainability.

The competition invited emerging recycled material suppliers to vie for funding, and Alliance support, to further develop their recycled product in a way that is economically sustainable and competitive in the construction market.

The NWPA ’Project Beacon’ solution was developed with competition partners Ecologiq, Metro Trains Melbourne (MTM), the state Urban Design Advisory Panel and Darebin City Council to:

• Engage with existing and prospective suppliers of recycled products

• Understand the challenges associated with using recycled materials in infrastructure projects

• Support investment to remove barriers to market to ease these challenges across LXRP and wider Victoria Infrastructure Delivery Authority (VIDA) projects

• Use the Keon Parade Project as a ’beacon’ to the industry to highlight NWPA and LXRP’s culture shift, from ’too hard’ to ’why not’?

When designing the approach to the project and its scope, the team identified two key goals:

• Overcome Barriers to Emerging Recycled Products – Throughout the industry suppliers are awarded start up or R&D funding to create their product, however they usually fail to fully commercialise products before seed funding runs out. This creates an almost insurmountable challenge of not being able to identify and solve barriers within construction timelines.

• Act as a Beacon to the industry – Signalling that recycled products are readily adoptable and provide a tangible and inspiring example of sustainability in action that people can look, see and touch.

NWPA chose to undertake a competition format to engage with, and challenge, emerging recycled materials suppliers to propose innovative solutions for use within urban realm projects. The initiative had three distinct phases:

Phase 1 – Competition

Suppliers were invited to submit proposals outlining their recycled materials solutions and the barriers they face. In total, 15 submissions were received. These were evaluated by a judging panel consisting of representatives from all the competition partners, against 22 judging and submission criteria spanning quadruple bottom line categories.

Phase 2 – Collaboration

Five successful suppliers and products were identified. They went on to work with NWPA’s key stakeholders to focus on overcoming a range of identified barriers including:

• Green premium costs and local manufacturing challenges

• Life cycle assessments and type approval issues

• Improving the connections between suppliers and buyers

• Addressing risk perceptions and overcoming change inertia

• Managing procurement and supply chain.

Phase 3 – Legacy

Working with successful suppliers on knowledge capture and lessons learned, the team promoted the competition process across LXRP and the industry while creating ongoing momentum to overcome barriers and incorporate recycled products to create a business-as-usual approach.

As part of engagement, 40 in-depth stakeholder interviews were undertaken with 135 stakeholders involved throughout the three-year process.

What were the OUTCOMES and how were those outcomes shared?

Project Beacon – Recycled First Competition enhanced the local recycled business economy, boosted the circular economy and achieved a range of sustainable outcomes. With Keon Parade LXRP only reaching practical completion in July 2024, its success is already paying dividends across several sectors, including growing the customer base for recycled product manufacturers.

Quantifiable Outcomes

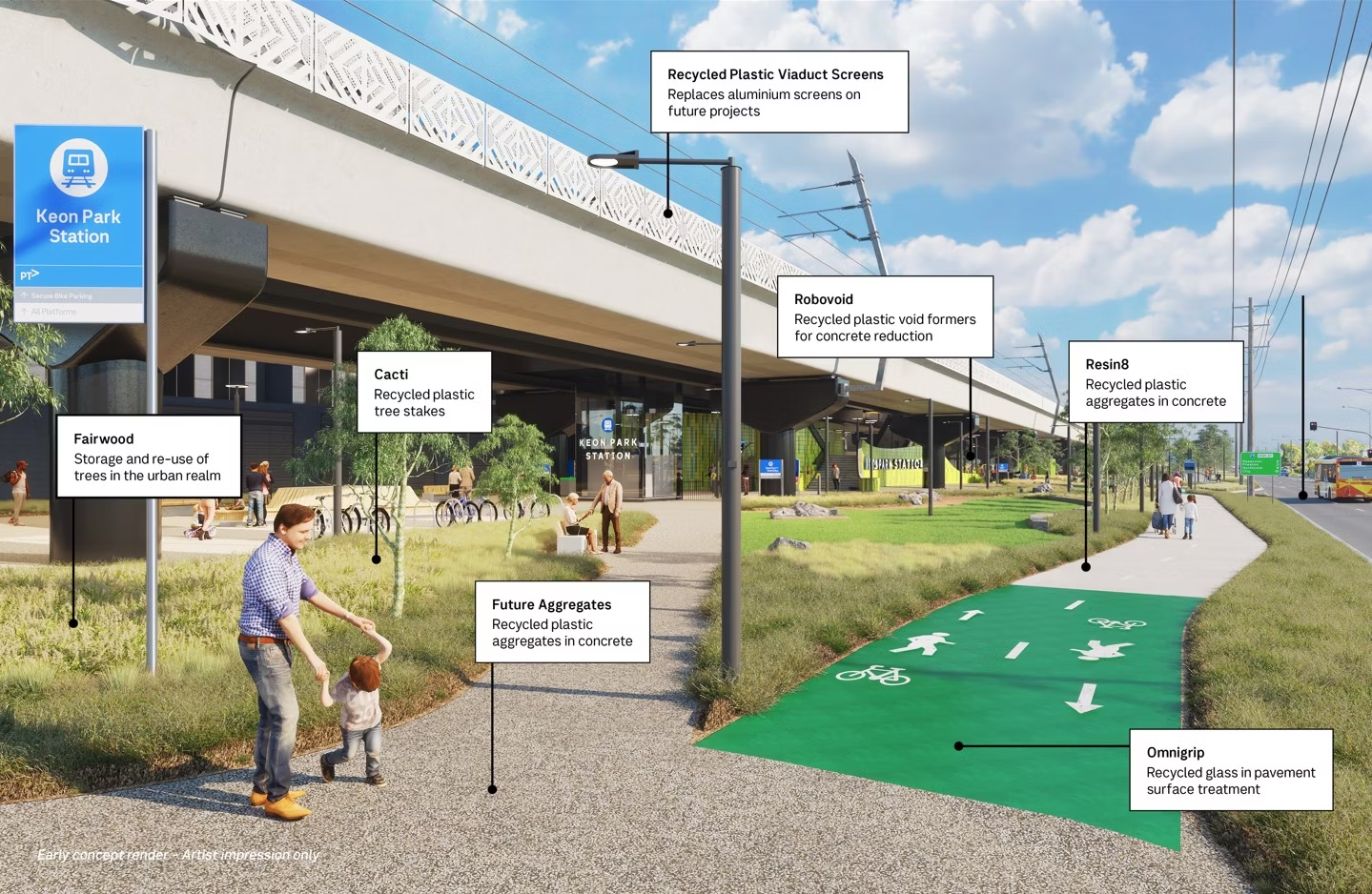

• Successful additional $800,000 investment in the circular economy, resulting in the creation of a ‘Recycled First Precinct’ at Keon Parade LXRP.

• Approval of five new recycled products for ongoing use across the entire MTM network.

• Developing strategic partnerships to implement:

o Recycled Plastic Viaduct Screen (designed for Melton LXRP) – 100t carbon emissions saved compared to a BAU aluminum screen, with an equivalent 120,000 plastic bottles diverted once installed in 2025.

o Recycled Plastic Concrete Void Formers – 1200 recycled plastic void cones used resulting in a 38% reduction in concrete used in the bike parking slab. More than 7kg of recycled plastic per sqm of construction diverted from landfill.

o Geopolymer Bench Seats – 90% carbon emissions reduction compared to standard station concrete seats.

o Recycled Plastic Aggregate in concrete pavements – More than 5000m2 of recycled plastic aggregate concrete with 50,000 plastic bottles diverted from landfill.

o Salvaged and Recycled Timber – Furniture grade timber was milled into seating and logs were salvaged for landscaping, reusing 40% of project timber at its highest and best use.

Investment and Commercial Viability

The $800,000 investment finalised product designs, trialed implementations and gained type approvals. Specialist SMEs provided their time, addressing and solving barriers to enable recycled products and materials to be applied within the construction design, removing perceived ‘Green Premiums’ to create supply chain opportunities.

Through our upfront investments as with the reusable moulds, suppliers are now suggesting recycled products as a viable alternative to virgin materials. With the support of NWPA’s Design and Engineering teams to overcome initial barriers and optimise installation, recycled products are becoming cost competitive or cheaper than traditional products, as shown with the recycled plastic viaduct screens achieving cost parity with aluminium.

Local Business Economy and circular economy

With the Recycled First policy targeting a circular economy within Victoria, the competition outcomes significantly enhanced the local business economy. Examples include:

• New partnerships in the supply chain opened procurement opportunities to implement void formers, strategic recycled timber, recycled plastic aggregates in concrete mixes, and geopolymer. Additionally, an entirely new product stream was developed in the design and procurement of recycled plastic viaduct screens.

• Investment into the production and approvals stages has lessened assessment timeframes with new clients.

• All strategic recycled suppliers selected for Keon Parade are located within 50 km of the project site, enhancing local spend and jobs.

• Victoria’s circular economy relies on infrastructure as a bulk purchaser of recycled products. Thus, facilitating these products boosts the scale of the entire circular economic cycle.

• Supplier Robovoid estimate that with the increased interest and forecast pipeline of work, they could employ an additional 20 people within 2-3 years.

Industry culture shift

• A change in perceptions of green premium thanks to the success of the competition bringing products and materials to market as cost competitive.

• New demonstrated and adoptable pathway for other projects to overcome these unique challenges. Collaboration is key to forming a deep understanding of the challenges faced by the supply-chain and in proposing new products to contractors.

• Recycled First, along with initiatives like the ISC’s iSupply program, create important new opportunities for sustainable procurement and product adoption in the infrastructure sector which deliver economic benefits for communities, companies and industries.

Sharing outcomes

The competition was designed as a showcase project to motivate and inspire the industry. Since completion in August 2024, NWPA has undertaken a significant number of industry engagements to share outcomes, with more to come, including:

• EcologiQ Lunch and Learn – ‘Driving sustainable outcomes through innovation’

- MTIA ‘Community of Practice’ – ‘Lessons for emerging career professionals from the Recycled First Competition’

- ARA Rail Sustainability Leaders’ Summit 2024 – Site Walk at Keon Parade – showcasing recycled products in the field

- Center for Regenerative Design & Collaboration (CRDC Global) launch in Melbourne – panel on strategic partnership between Keon Parade and Resin8

- 2024 International Public Works Conference – critical partnerships with Councils for achieving recycled first and circular economy outcomes.

Describe WHO benefited from your initiative, innovation, or approach?

Project Beacon - Recycled First Competition set a collective mindset to effectively bring the competition finalists’ products to fruition while ensuring they were incorporated into NWPA’s long term design and the procurement strategy. The multiple beneficiaries include:

Direct Beneficiaries:

Recycled suppliers and emerging technologies

The successful suppliers were supported by $800,000 in development and implementation investment for R&D, design and the type approvals process, ensuring products were suitable for application.

ROBOVOID has seen increased interest, with their enquiries doubling since working on Keon Parade.

Curvecrete has received increased orders for their seating products and are in discussion for large-scale partnerships using their robotic mould technology.

RESIN8 reports that inclusion of their products at Keon Parade has resulted in improved confidence within the construction industry for further utilisation of this product in upcoming projects.

“Since the successful application of ROBOVOID at Keon Parade, ROBOVOID has been included in the design / specified on other infrastructure projects in Victoria, including in road, rail and water sectors. There is increasing interest from interstate and international clients on the back of the publicity received from the Keon Parade project.”

Scott Olding, Director, Robovoid

Indirect Beneficiaries:

The Government’s ‘Recycling Victoria – A New Economy Report’ identified that transitioning to a circular economy could potentially boost Victoria’s economy by up to $6.7 billion by improving material efficiency and recycling, helping create more than 3,900 new jobs and by helping businesses grow in new ways and create new sectors in the Victorian economy. As such, indirect beneficiaries include:

Local communities and businesses

Communities benefit from the circular economy through savings as the use of recycled products become increasingly cost-effective, driving re-use and conserving natural resources. Initiatives like the Recycled First Competition drive innovation within the supply chain, support local jobs, reduce waste and carbon emissions.

Sustainability Professionals and Organisations

The competition provides a roadmap for sustainability professionals and organisations to adopt a similar approach in the engagement, investment and application of new and emerging sustainable projects. The work already undertaken, and the lessons learned, saves on upfront costs and addresses barriers to implementation.

Government bodies and project owners

Project Beacon provides a commercial and governance model which government and other project proponents can use to support their circular economy goals and implementation within the supply chain.

What LEGACY and UN SDG CONTRIBUTION was achieved?

The competition challenged both suppliers and projects looking to use new and emerging recycled products and materials. While the competition has implemented products on the Keon Parade Project, the NWPA team has also embedded the successful products into their next two projects, with plans to continue to work with suppliers to become business-as-usual inclusions in the procurement process.

Local Industry Advancement

Facilitating [initiatives] like this supports knowledge sharing between other states and jurisdictions, and showcases the quality finish that recycled materials can provide. It helps build demand for the Victorian supplier chain and supports new partnerships and opportunities for their businesses.

Polly Gourlay-Phillip, Acting Implementation Manager, Ecologiq

The application of recycled products has accelerated market opportunities for local industries, as is the case with ROBOVOID in Tottenham, Victoria and RESIN8 in West Footscray, Victoria. The expansion of these products supports further economic opportunities and job creation in the circular economy.

Roadmap for Others

The competition provides a framework for other industries to use to engage with suppliers and develop their own process to enable the procurement and application of recycled products and materials. NWPA is currently developing clear documentation such as an Infrastructure Tree Reuse Guide and a Recycled Plastic Viaduct Screens Engineering Report to ensure a written legacy of the project is shared widely.

The ISC WhitePaper “Challenges and Opportunities in the Procurement of Sustainable Products and Services in Infrastructure” outlines five proposed procurement solutions. NWPA has provided the industry with an exemplar case study of how all five solutions can be delivered on a project, through education, alignment, incentivisation, early inclusion and knowledge sharing.

Breaking Down Barriers

The competition format addressed and solved a number of market and adoption barriers, identified by the ISC, including:

• Cost-based, short-term decision-making – The competition demonstrated opportunities can be realised through effective supplier engagement, confirmed investment and a strategic pathway to market.

• Lack of awareness - The competition mechanism brought recycled products suppliers and the construction industry together, with outcomes shared across a range of industries.

• Risk management – The agreed process was carefully managed with the support of all stakeholders.

• Budget constraints – Investment supported development hours which enabled product acceptance, type approvals and application into design.

• Logistical complexities – The governance approach directly considered and addressed challenges in sourcing, transporting, and implementing sustainable products.

• Lack of visibility – The competition and subsequent application of products at Keon Parade promoted the range of products in situ, providing showcase opportunities for suppliers.

This Project advanced the following SDGs:

SDG 8: Decent Work and Economic Growth

New and emerging recycled products create new industry and job opportunities, contributing to economic growth. In turn, the construction industry can promote sustainable outcomes, demonstrating economic gains and benefits.

SDG 9: Industry, Innovation and Infrastructure

Promotes sustainable infrastructure by encouraging recycled materials in construction. It uses the competition model to drive collaboration between stakeholders and overcome barriers to develop and use recycled material solutions.

SDG 11: Sustainable Cities and Communities

Accelerates sustainability practices by focusing on the use of recycled materials, transforming the approach of how these products were considered and used in public infrastructure. The process can be applied across other industries to incorporate recycled materials in urban infrastructure.

SDG 12: Responsible Consumption and Production

Promotes responsible production, aiming to reduce waste generation through recycling and reuse.

SDG 15: Life on Land

The reuse of site salvaged timber, through the partnership with CERES Fair Wood, contributes to the sustainable management of forests.

SDG 17: Partnerships for the Goals

Collaboration with suppliers to achieve sustainable goals, share knowledge and skills and create positive outcomes for infrastructure projects.